Fitter Lab

The ITI Fitter trade lab is a dedicated space within an Industrial Training Institute (ITI) where students pursuing the Fitter trade gain practical hands-on experience and develop their skills in various aspects of fitting and assembling mechanical components. The lab is designed to provide a simulated industrial environment, allowing students to apply the theoretical knowledge they acquire in classrooms and workshops to real-world situations.

The ITI Fitter trade lab is equipped with a wide range of tools, machinery, and equipment that are commonly used in the fitting and assembly processes. These may include cutting tools, drilling machines, grinding machines, lathe machines, milling machines, welding machines, power tools, and measuring instruments such as vernier calipers, micrometers, and gauges. The lab may also have workbenches and storage facilities for organizing the tools and components.

In the lab, students learn various essential skills related to the fitting trade. They gain proficiency in reading technical drawings and blueprints, understanding engineering symbols, and interpreting measurements and dimensions. They practice marking, measuring, and cutting different materials to precise specifications. They learn how to drill holes, tap threads, and perform threading operations on components. Additionally, they develop skills in grinding, filing, and shaping metal surfaces for proper fitment.

The ITI Fitter trade lab provides students with opportunities to assemble and disassemble mechanical components and systems. They learn about different types of fasteners, such as nuts, bolts, screws, and rivets, and gain expertise in their proper selection and application. Students also learn about different types of joints, including mechanical, welded, and brazed joints, and practice creating these joints using appropriate techniques and materials.

Electrician lab

The ITI Electrician trade lab is a specialized facility within an Industrial Training Institute (ITI) that provides students with practical training and hands-on experience in the field of electrical work. The lab is designed to simulate real-world electrical installations and systems, enabling students to develop their skills and knowledge in electrical wiring, troubleshooting, and maintenance.

The ITI Electrician trade lab is equipped with a wide range of electrical tools, instruments, and components necessary for electrical work. These may include wire strippers, pliers, screwdrivers, multimeters, voltage testers, circuit breakers, switches, sockets, conduit pipes, and electrical panels. The lab may also have workbenches, electrical boards, and mock-up installations to replicate different types of electrical setups.

In the lab, students learn the fundamentals of electrical wiring and circuitry. They gain knowledge about electrical symbols, diagrams, and codes, and learn how to read electrical drawings and blueprints. Students practice measuring and cutting electrical cables, stripping insulation, and connecting wires using appropriate techniques such as soldering, crimping, or using connectors. They also learn about different types of electrical conduits and cable trays and gain proficiency in their installation.

The ITI Electrician trade lab provides students with hands-on training in the installation and maintenance of various electrical systems. They learn to install electrical fixtures, switches, and sockets in residential, commercial, and industrial settings. They gain expertise in the installation of distribution boards and circuit breakers, ensuring proper wiring connections and load balancing. Students also learn about the installation and troubleshooting of lighting systems, motor control circuits, and power distribution systems.

In addition to installation, students learn how to troubleshoot and repair electrical faults. The lab provides a controlled environment for students to practice diagnosing electrical problems, such as short circuits, open circuits, and voltage fluctuations. They learn to use electrical testing equipment, such as multimeters and voltage testers, to identify and rectify faults. Students also acquire knowledge of electrical safety practices and are trained to adhere to safety regulations while working with electricity.

Electronics Mechanic Lab

The ITI Electronics Mechanic trade lab is equipped with a wide range of electronic tools, instruments, and components necessary for electronic work. These may include soldering irons, multimeters, oscilloscopes, function generators, power supplies, breadboards, resistors, capacitors, transistors, integrated circuits (ICs), and various electronic modules. The lab may also have workbenches, electronic testing stations, and computer systems for software development and programming.

In the lab, students learn the fundamental concepts of electronics and electronic circuitry. They gain knowledge about electronic components, their functions, and how they are connected in circuits. Students practice soldering techniques and learn to assemble and solder electronic components on breadboards or printed circuit boards (PCBs). They also gain proficiency in reading circuit diagrams and schematics, understanding electronic symbols, and identifying components.

The ITI Electronics Mechanic trade lab provides students with hands-on training in the assembly, testing, and troubleshooting of electronic circuits. They learn to design and build basic electronic circuits, such as amplifiers, oscillators, and power supplies. They gain expertise in using electronic instruments and equipment to measure voltage, current, and resistance, as well as to analyze and diagnose circuit faults. Students also learn about different electronic communication systems, such as radio, television, and telecommunications, and may have the opportunity to work with related equipment and devices.

In addition to circuit assembly, students learn how to troubleshoot and repair electronic faults. The lab provides a controlled environment for students to practice diagnosing and rectifying common electronic problems, such as faulty components, open or short circuits, and signal distortions. They learn to use oscilloscopes, multimeters, and other diagnostic tools to analyze electronic signals, identify faulty components, and replace or repair them.

Draughtsman Civil

The ITI Draughtsman Civil trade lab is a specialized facility within an Industrial Training Institute (ITI) that provides students with practical training in civil drafting and design. Equipped with tools like drawing boards, CAD software, and drafting instruments, the lab enables students to develop skills in architectural drawing, structural design, and construction planning. In the lab, students learn to create accurate architectural drawings, including floor plans, elevations, and sections, while adhering to industry standards and codes. They also gain expertise in structural design and detailing, representing elements like beams, columns, and foundations in drawings. Additionally, students learn construction planning and project management, creating construction drawings and participating in collaborative projects. Safety practices are emphasized, and students are trained in handling tools, workplace safety, and building codes. Overall, the ITI Draughtsman Civil trade lab plays a vital role in preparing students for careers in architectural and structural drafting, construction planning, and project coordination.

Draughtsman Mechanical

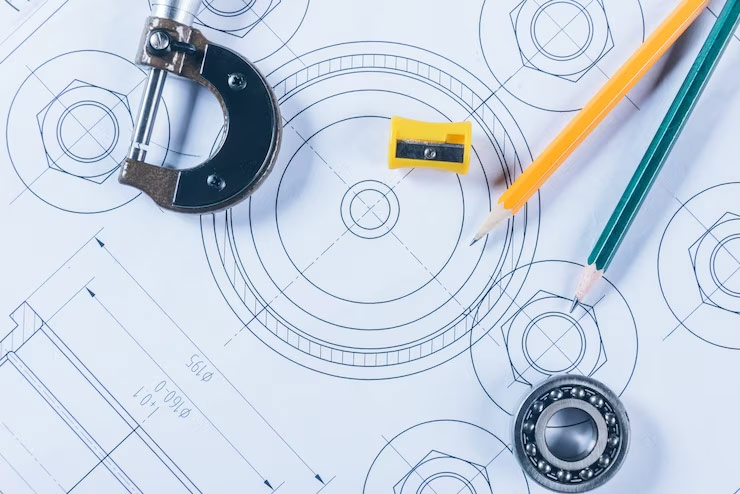

In the lab, students learn the principles of technical drawing and gain proficiency in using drafting tools such as drawing boards, T-squares, scales, and compasses. They also receive training in computer-aided design (CAD) software, which enables them to create detailed 2D and 3D mechanical drawings and models.

The ITI Draughtsman Mechanical trade lab focuses on teaching students the fundamentals of machine design. Students learn to create precise and accurate drawings of machine components, assemblies, and mechanisms. They gain knowledge about dimensioning, tolerancing, and material selection, ensuring their designs meet industry standards and specifications.

The lab provides students with practical experience in designing mechanical systems and equipment. They undertake projects that involve creating layouts, assembly drawings, and technical documentation. Students learn about manufacturing processes such as machining, casting, and fabrication, and understand how to incorporate these processes into their designs.